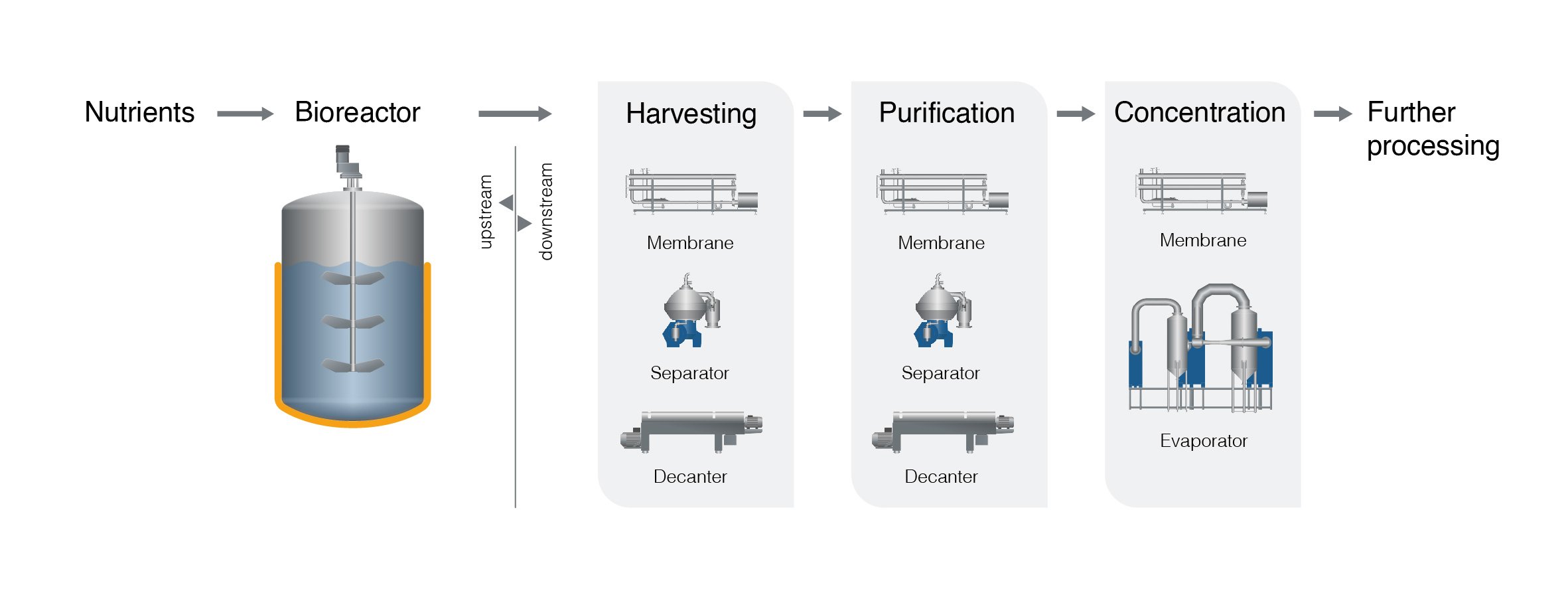

Cellular agriculture systems – Downstream processing

Harvesting

Cell harvesting is a key step in all fermentation-based production, and the choice of separation system greatly impacts product quality, yield, and cost for downstream processing. Tailoring the harvesting system to the type of process and microorganisms used is therefore crucial for high plant performance.

Cell harvesting

Alfa Laval has supplied separation equipment to the fermentation industry for several decades. We offer disc stack separators and decanters for all cell types and plant sizes, and our application specialists help you select the perfect separation system for you.

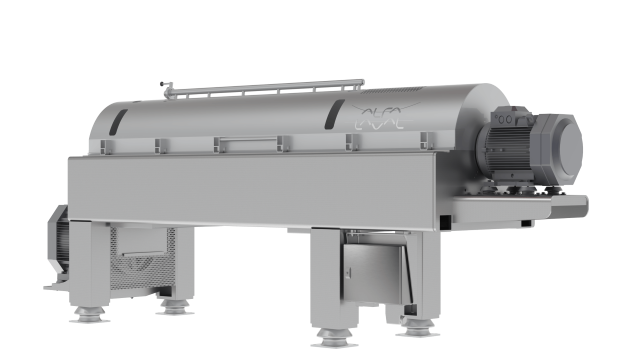

Decanter centrifuges

The separation efficiency in the harvesting stage determines the yield of the process to a high degree. Therefore, choosing separation equipment that matches your process and microorganism is key to achieving optimum results.

For biomass fermentation processes, Alfa Laval Foodec decanter centrifuges are widely considered to be the best choice due to their exceptional solids handling capacity, first-class cleanability, hygienic design, and low maintenance requirements.

Foodec units are available with a two-phase gravity liquid discharge or a pressurized liquid discharge (paring disc) that can be used when foaming is an issue.

If there are variations within the feed, Foodec decanters can also be fitted with Alfa Laval PondCtrl, an automated system for controlling the liquid level in the decanter centrifuge during operation. PondCtrl enables quick adjustments of the separation process, speeds up cleaning, and facilitates starting and stopping procedures, resulting in increased uptime and yield.

Separators

An Alfa Laval separator is the perfect choice for more stringent harvesting duties. For example, the Alfa Laval Bactofuge separator is ideal for removing microbial cells from high-density broths in industrial fermentation applications. Thanks to its continuous solids discharge, a Bactofuge separator offers outstanding throughput – even at high cell loads.

Featuring Alfa Laval’s unique hermetic design, Bactofuge provides very gentle acceleration of the broth, resulting in minimal cell lysis and more efficient separation. The hermetic design also reduces energy consumption by up to 40%. In addition, it ensures an air-free environment inside the separator, thereby minimizing foaming and the risk of contamination.

Purification

A purification stage, where impurities are removed, is often required before the final formulation of the product. The design of the purification process differs depending on whether you are producing biomass or a specific ingredient.

Removing impurities through washing

For biomass fermentation processes, purification is often performed by washing the product. First, water is added to the harvested cells, and then one or several separators or decanters remove the excess water and the impurities.

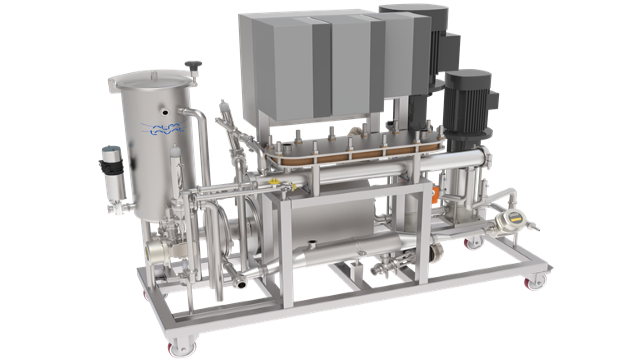

Purification using membranes

In precision fermenting, the product is a specific ingredient in the liquid, and some fine suspended impurities are still present after the harvest. These can be removed in a microfiltration or open ultrafiltration process, where the target protein (or other molecules) is recovered in the permeate while the suspended impurities are retained.

Alternatively, a fine ultrafiltration membrane can be used if the target molecule must be purified from fine soluble impurities. In this process, water is added right before the filtration stage, and the water and compounds with low molecular weight, like sugar and salts, go through the membrane while the product remains in the retentate.

Concentration

One of the final steps in a fermentation-based protein production process is to concentrate the product by removing excess water. This can be done in two ways, through evaporation or membrane filtration.

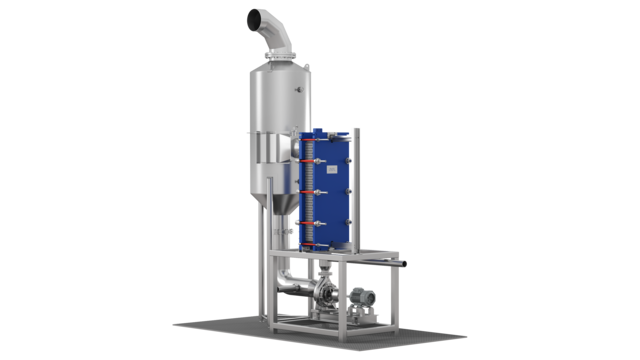

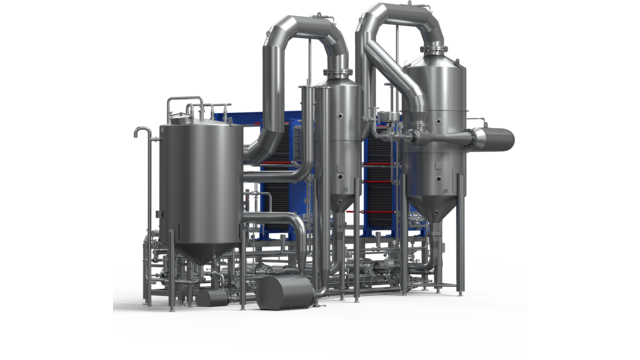

Concentration through evaporation

Alfa Laval offers two different evaporation systems, AlfaVap and AlfaFlash. Both are based on plate heat exchanger technology, resulting in benefits such as:

- Compact size – an Alfa Laval evaporation system is much smaller than corresponding shell-and-tube-based systems

- Gentle heating and short retention times make them especially suitable for heat-sensitive products where there is a risk of degradation and discoloration

- Minimal maintenance and long running times thanks to the self-cleaning effect in the plate heat exchangers

- Very high operational reliability

AlfaVap is designed for low to medium-fouling liquids, and AlfaFlash is for high-fouling liquids.

Concentration through membrane filtration

Another way to concentrate the final product is to use fine membranes to remove excess water. In this case, the product is concentrated as the water is removed through the membrane.

Alfa Laval’s reverse osmosis and nanofiltration membranes are perfect for this application. The main benefits of using membrane filtration compared to evaporation are that the product is not heated, which eliminates the risks of degeneration and discoloration, and the energy consumption is much lower.

Complete downstream processing systems

Alfa Laval can provide complete system solutions where the bioreactor harvesting, purification and concentration equipment are integrated into a working processing line and connected with hygienic fluid handling and thermal exchange equipment such as valves, pumps, piping and heat exchangers. Additionally, Alfa Laval can provide automation solutions that enabling accurate control and easy monitoring of the entire process.