Insect processing

Extract maximum value from your raw material with a wet rendering system for insect protein and lipids. Minimal heating of the raw material and excellent hygiene gives your products supreme quality and first-class taste, ensuring a high market price. Whether you are just starting at pilot-scale or are running a full-scale insect protein processing plant, we invite you to contact us for a discussion with our application experts on scaling up and process optimization to support your development.

Unlike others, we can provide whole solutions from rearing to end-products

- Low-temperature process, resulting in feed and food-grade protein meal and lipids of the highest quality

- Low energy and water consumption ensure low OPEX and a sustainable end-product

- Hygienic design and proven CIP solutions make it easy for you to comply with stringent hygienic standards

- Reliable process solutions with high yield and a modular design for maximum flexibility and easy scale-up

- Try out new ideas, make test batches, and validate performance in our fully equipped test centre or at your own site

Alfa Laval is unique in offering complete scalable solutions for insect-based protein processing built on Alfa Laval's core technologies, spanning the entire production chain from rearing to final products. Together with our partners, we can provide complete production lines, including the stages before and after rendering. If you prefer, we can supply individual modules or components too.

Having one supplier for your insect processing line minimizes risk and enables optimization of the complete plant.

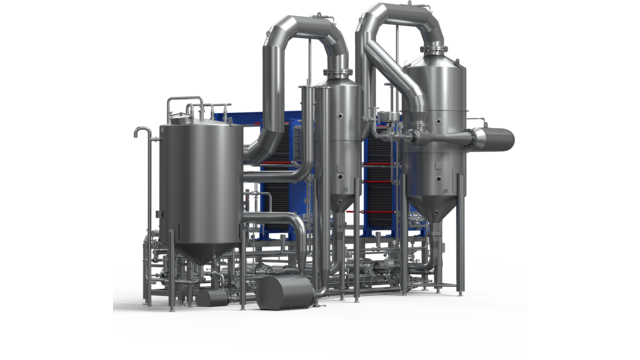

Our compact wet rendering systems are modular and scalable and can process a wide range of insect species, allowing you to easily expand your business and enter new markets profitably.

We were the first movers in insect processing, and we have decades of experience in the protein industry. Let us guide you in your journey and create the optimum solution.

Overview of insect protein processing

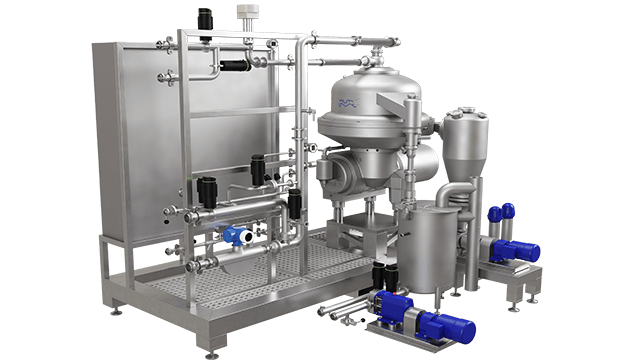

Alfa Laval’s wet rendering systems are ideal for producing food and feed-grade protein and lipids from insect raw material. In cooperation with selected partners, we can provide entire production lines, including upstream and downstream equipment such as dryers, meal handling systems, and rearing solutions.

All our insect-based-protein processing systems come with our performance guarantee on the entire process, ensuring peace of mind and expected return on investment.

Our insect protein processing systems extract all the protein from the raw material and separate most of the lipids from the protein meal. The exact outputs depend on your insect species, the quality of the raw material and its nutritional composition. Please contact us for further discussions.

Did you know that …

- … the demand for insect protein could reach half a million metric tons by 2030?

- … insect protein is characterized by very high palatability and digestibility?

- … the value of food-grade protein is higher than feed-grade?

- … pet food currently is the largest market for insect protein?

Read about the latest insect protein trends

Comparing dry and wet rendering

Two different processes can be used for insect protein processing: dry rendering and wet rendering. Alfa Laval provides equipment for both processes and complete production lines for wet rendering.

One of the main benefits of wet rendering is that the raw material is heated for a much shorter time than in a dry rendering system, resulting in significantly better taste, visual appearance, and nutritional value for the lipids fraction.

A second major benefit is that a wet rendering system can be cleaned more effectively, making it possible to produce food-grade products meeting the highest hygienic standards.

Take advantage of the possibilities in our test centre

We are glad to provide test equipment that you can evaluate at your site, allowing you to test our products together with your existing equipment and raw material before purchase.

We also invite you to conduct tests at our test facility in Denmark. Here we have a complete equipment setup covering all process stages, allowing you to try out new ideas, produce test batches, or validate the performance of Alfa Laval equipment – all with the full support of our process experts.

Scaling up your business

Our application experts are ready to support your development and advise you on the best ways to industrialize your process as you move from lab to pilot plant and finally to full-scale production. They help you optimize your process in terms of profitability, uptime, yield, taste, hygiene, and product quality as your business grows.

Alfa Laval insect-based-protein processing systems are based on a modular design to maximize flexibility and future-proof your investment, making scaling easy.

Contact us to book a meeting where we discuss how we can assist you in your expansion.

Maximize sustainability by minimizing energy consumption

One significant benefit of an Alfa Laval wet rendering system is the low energy consumption resulting from how the dewatering is performed.

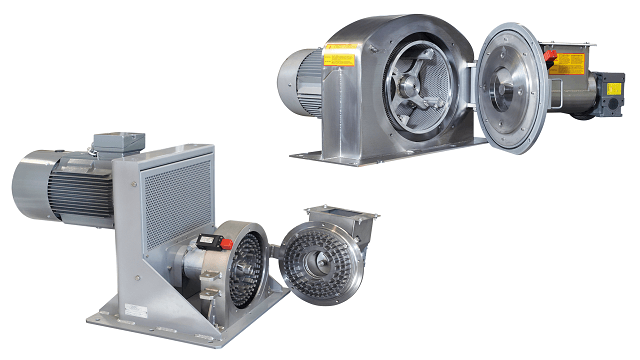

The first dewatering stage in an Alfa Laval wet rendering system is mechanical dewatering in a decanter centrifuge. In a dry rendering system this is instead done in a cooker. Removing water using G-forces in a decanter consumes far less energy than boiling the water off in a cooker, which reduces energy consumption significantly.

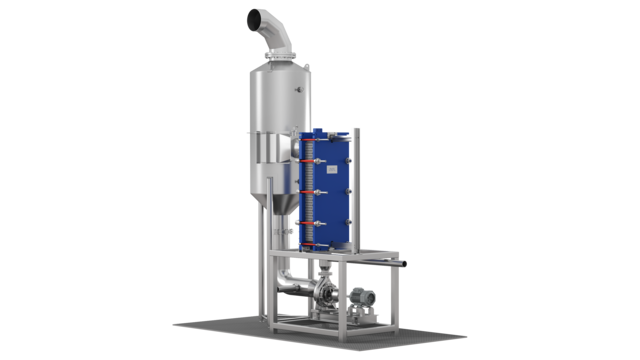

The second dewatering stage is the evaporation system, where stickwater is concentrated. Alfa Laval evaporation systems are built on our highly effective plate heat exchanger technology and use a multi-step configuration that reuses heat several times. Reusing the heat makes the boiling process much more efficient in an evaporator than in a cooker.

In addition, a plate evaporator system is a much more modular and compact solution than a shell-and-tube-based system, with a significantly lower installation cost.

Comparing the total energy consumption, an Alfa Laval wet rendering system roughly consumes 50% less energy than a dry rendering system

Turning food waste into valuable larvae feed

Producing insect protein is one of the most circular ways to produce food. A key factor is that the larvae feed on waste from farming, breweries, food production, and kitchens. Before it is given to the larvae, the feed is often processed to optimize the nutritional value and maximize larvae growth.

Alfa Laval offers solutions for upcycling your waste into valuable insect feed, including evaporators and decanters to finetune the water and lipids content of the feed.

Complete service solutions

Combining a systems approach to service with extensive process expertise, we optimize the performance of your entire process by identifying and addressing the root causes of your issues.

We offer a complete range of services spanning the entire lifetime of your plant. Our global service network covers nearly 100 countries, meaning quick and professional support is always close.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you focus on your daily operation, we handle the planning, procurement and execution of the required service measures.