NEAR Marine newsletter

Meeting the challenges of 2020

When the 2020 global sulphur cap enters into force, it will impact marine fuels, marine vessels and the marine industry as a whole. Alfa Laval is ensuring customers are prepared, for fuel challenges and more.

The future builds on a century of steam

Welcome to the NEAR Marine special edition newsletter about Aalborg boilers’ 100th anniversary. In 1919, when the first marine boiler left the Aalborg Shipyard in Aalborg, Denmark, no one could have known the significance it would have. 100 years later, the Aalborg name has become synonymous with boiler expertise.

NEAR marine June 2019

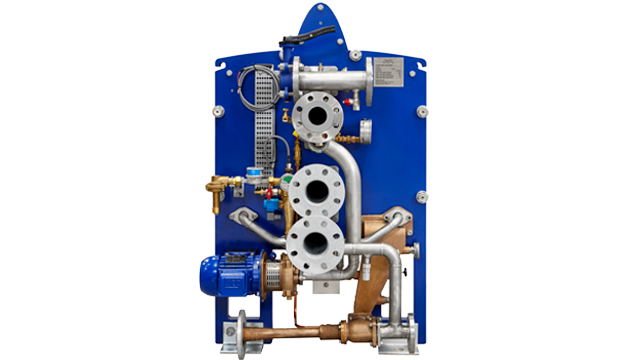

Cost-saving new flexibility with PureSOx

When the first vessel set sail with Alfa Laval PureSOx ten years ago, it had a hybrid system on board. Capable of operating in either closed or open loop, hybrid systems balance the ability to meet tougher discharge regulations with total operating economy. Today, a new PureSOx water cleaning system (WCS) offers more cost-saving flexibility than ever.

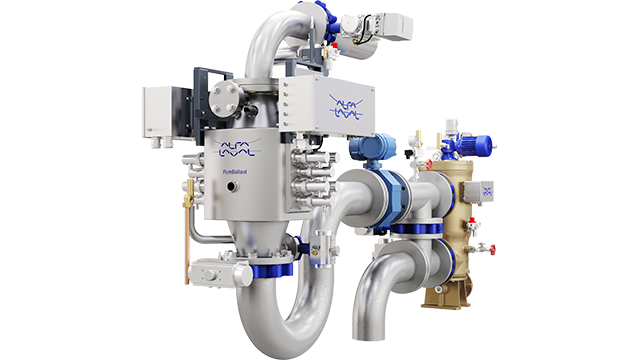

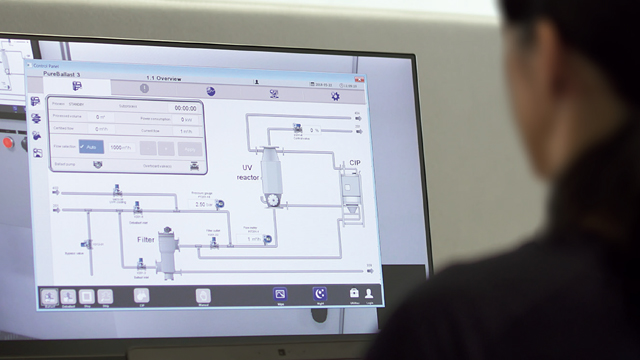

PureBallast 3 meets tough challenges with ease

Alfa Laval PureBallast 3, the third generation of the leading ballast water treatment technology, now has minimized holding time in United States waters – and is ready for revised G8 requirements in 2020.

More steam without burning more fuel

Why let valuable energy go up in smoke? The Alfa Laval Aalborg Micro is an extremely compact new waste heat recovery boiler that maximizes the energy efficiency of auxiliary engines.

Solutions to meet the sulphur cap

Alfa Laval’s fuel line expertise encompasses the whole chain from bunker tank to engine. As fuel sulphur regulations change operations on board, updated technologies and smart recommendations are helping customers meet the new challenges.

Marine engine lubrication made compact

Lube oil quality impacts engine lifetime. Efficient oil cleaning is crucial for minimizing marine engine wear and damage, and for ensuring consistent operation at peak performance. The inevitable changes in fuel types after 2020 make it necessary to reassess lube oil strategy.

Fresh water with an even smaller footprint

The Alfa Laval AQUA Blue fresh water generator cut seawater needs and electrical power consumption in half. Now the AQUA Blue Mini cuts footprint by 40% for smaller vessels.

Securing vessel performance worldwide

Service is integral to performance – throughout a vessel’s lifetime and wherever it sails. Alfa Laval service expertise helps avoid costs today, but also saves over time.

NEAR marine March 2019

Repairing boilers and building trust: Alfa Laval Field Service Engineers go the distance for customers

This year marks 100 years since the first Aalborg marine boiler was shipped from Aalborg, Denmark. As Alfa Laval celebrates the centennial, the renowned Aalborg name continues to travel the world, represented especially by Alfa Laval Field Service Engineers.

Alfa Laval PureSOx scrubber systems – 10 years at sea

The arrival of 2019 leaves just one year until the global sulphur cap becomes reality. But as the marine industry scrambles to ready itself, an important milestone has already been reached. The new year marks a decade since the first vessel set sail with an Alfa Laval PureSOx scrubber on board.

New 1500 m3/h PureBallast 3 reactor for large flows

With a new UV reactor size of 1500 m3/h, Alfa Laval is increasing the installation flexibility of Alfa Laval PureBallast 3. The new reactor, which handles 50% more volume than the current largest reactor size, is good news for tankers and other vessels with large ballast water flows.

PureSOx Connect makes it easier to comply and optimize

Alfa Laval PureSOx is at the forefront of SOx scrubbing technology, but also of simplifying compliance. PureSOx Connect is a growing range of data-driven services that bring new ways to save time and money.

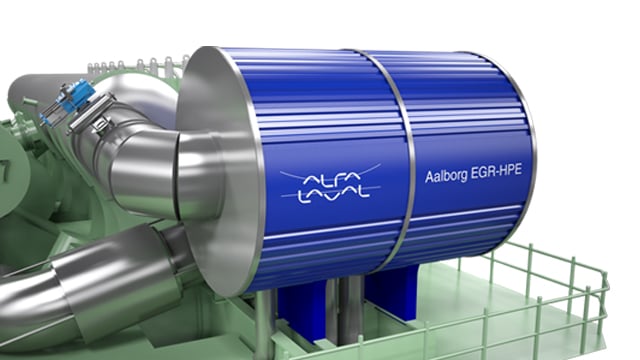

NOx compliance and savings: EGR water treatment with a difference

Alfa Laval PureNOx technology has long been the choice for water treatment in Exhaust Gas Recirculation (EGR). In response to the global sulphur cap, it will soon be available in two solutions – PureNOx LS (Low Sulphur) and PureNOx HS (High Sulphur).

Optimizing the entire fuel line to address 2020 fuel challenges

Alfa Laval’s fuel treatment portfolio encompasses the whole chain from bunker tank to engine. As fuel sulphur regulations change operations on board, separators and other technologies are being optimized and updated to meet the new challenges.

Supporting LNG with dual-fuel boilers and more

As emissions legislation tightens, the number of customers turning to gas is growing. Alfa Laval is a trusted and experienced supplier of systems for gas and multi-fuel projects, especially when it comes to boilers.

Putting service and marine customers ahead

Service is much more than a nice-to-have. It has an integral role in securing vessel performance – throughout the vessel’s lifetime and wherever it sails.