Alfa Laval BlueBox SA ends oily water compliance worries

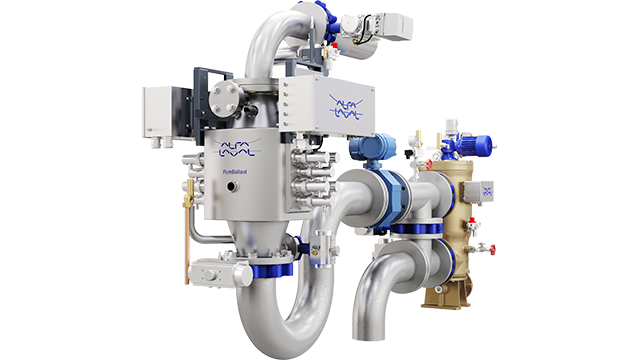

Fines and criminal charges for non-compliant discharge of oily water continue to make headlines. Alfa Laval PureBilge has long helped customers avoid such problems, and now the Alfa Laval BlueBox SA offers peace of mind to those with other oily water treatment solutions.

DATE 2023-11-27

The enforcement of oily water discharge requirements has grown increasingly strict, with high-profile cases resulting in massive fines or even jail sentences. Ship owners can rest easy if they have an effective solution like Alfa Laval PureBilge, whose centrifugal separation technology handles both emulsions and rough seas. But for customers with static coalescers or older, less optimized separators, oily water can be a real a source of worry.

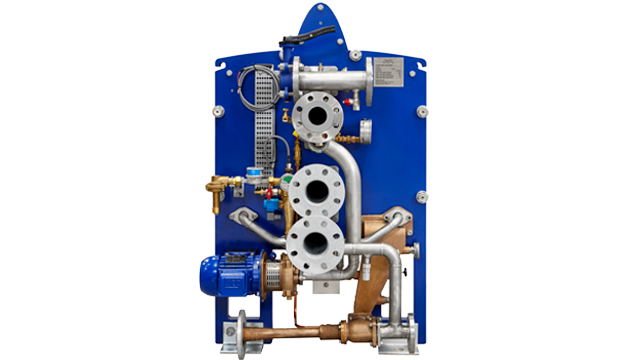

This makes the new BlueBox SA welcome news. The BlueBox SA is a tamper-proof oil content monitor and data recorder that can be used with any oily water separation solution. Based on the original BlueBox, which is integrated into PureBilge, the BlueBox SA is a standalone unit for upgrading an existing oily water setup.

An upgrade for any oily water separator

The BlueBox SA monitors the oil content of the water for overboard discharge, making sure that it falls within the set 5 or 15 ppm limit. If the oil content is too high, the BlueBox SA prevents the overboard discharge valve from opening, ensuring that no non-compliant discharge can occur.

The solution can be used to upgrade an existing oily water separator, regardless of its age or maker, as well as on newbuild vessels. Besides monitoring clean water tanks, where a standalone oil content monitor (OCM) is required, the BlueBox SA can be used to monitor clean drain tanks, which collect steam condensate, boiler drainage, cooler air drainage and more.

Added insurance for those with coalescers

The Blue Box SA is an important safeguard for ship owners and operators, and particularly for those with static coalescers. Though able to pass the land-based tests for type approval, coalescers are batch systems whose performance and capacity are limited – especially in rough seas. Due to their heavy reliance on polishing filters and the excessive attention they require, customers like RollDock are abandoning coalescers in favour of centrifugal separation technology.

To find out more about how centrifugal separation meets the requirements of today’s strict oily water discharge enforcement, download the Alfa Laval white paper Bilge water compliance issues , or view the RollDock case story

Other articles

Etichete

Tot