Base Minerals and Mining

Alfa Laval has a range of equipment and the knowhow to help you optimize key processes in base mineral beneficiation and extraction applications. Our aim is to help you boost capacity, save space, raise yields and ensure operational safety. Applications covered include heating, cooling, heat recovery and condensation as well as concentrate and tailings dewatering and intake water treatment by evaporation.

Highly robust equipment with minimal operator intervention

- Proven short payback time

- High volume capacities and space-saving equipment designs

- Maximize recovery of valuable products and minimize waste

- Contained process promotes good and safe working conditions

- Water re-use helps boost operational sustainability

Tackling tailings safely and sustainably

Alfa Laval decanter centrifuges are a proven, efficient solution for large-scale dewatering of tailings and removing the finest particles that conventional solids control equipment is unable to deal with. They offer a cost effective, sustainable and, above all, safe solution to manage tailings, acting as a complement to traditional separation systems such as thickeners, sedimentation basins and filters or replacing old systems altogether.

Solicitați noi standarde

Prezentarea celor mai moderne schimbătoare de căldură cu plăci și garnituri din lume. Descoperiți cum linia noastră de schimbătoare de căldură cu plăci și garnituri de nouă generație, vă oferă eficiență sporită, fiabilitate mai bună și o mai mare capacitate de service.

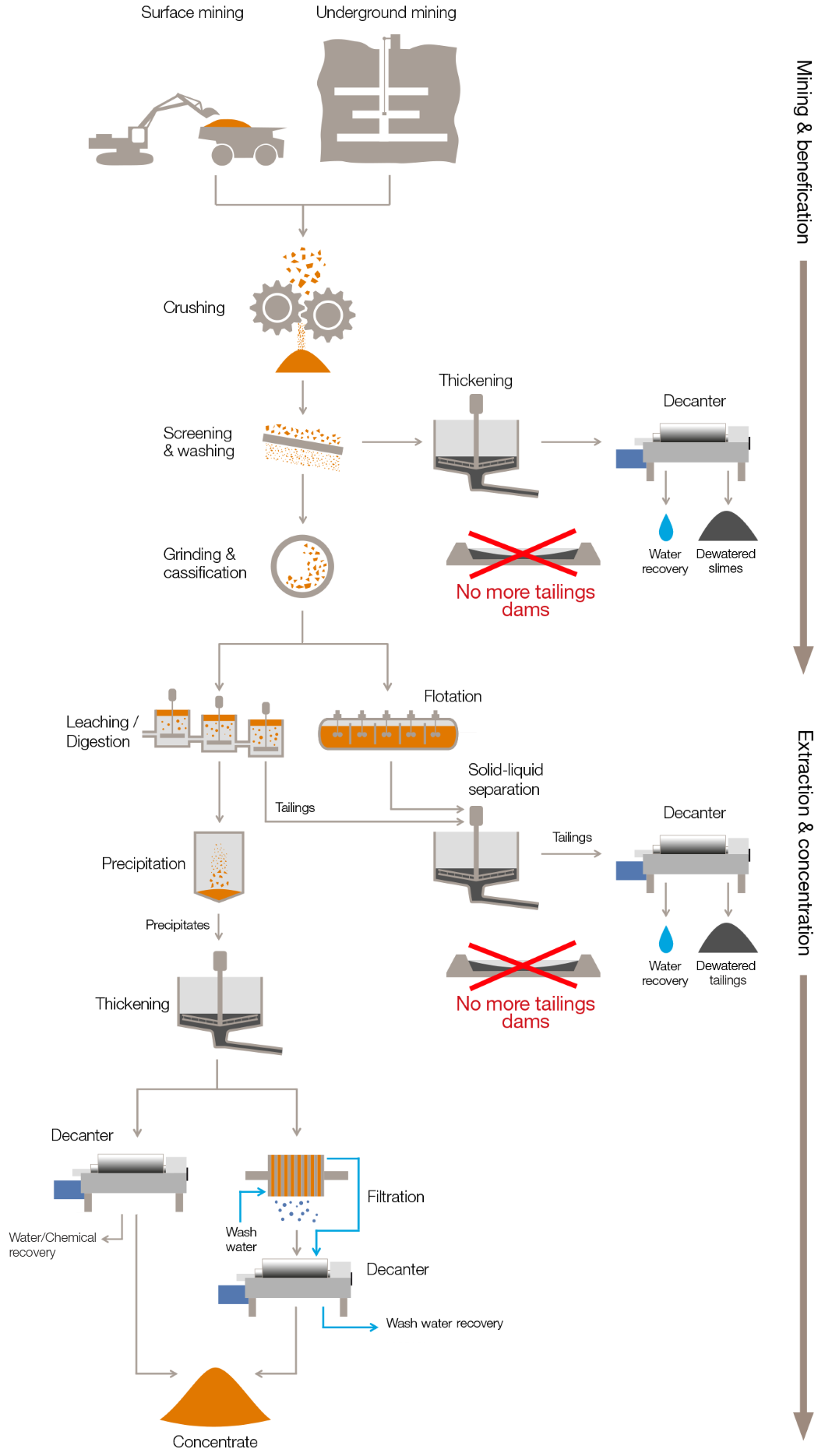

Opportunities throughout your process

Explore the mining flowchart and discover how an Alfa Laval decanter centrifuge can help streamline your operations in various process areas.

What's your treasure?

Alfa Laval offers robust decanter centrifuges as well as gasketed, welded and spiral heat exchangers, each optimized for specific duties and operating conditions in mineral processing. Find out more by downloading the brochure.

Alumina

The extraction of alumina involves energy-intensive processes, such as digestion, evaporation and liquor heating. The challenge? How best to recover and reuse process waste heat to reduce costs and raise yields. To succeed, aluminium manufacturers require process know-how as well as highly reliable equipment and smart services that optimize performance, ensure uptime and increase profitability.

Copper

To get the most out of energy-intensive copper processes – from leaching to electrowinning, copper producers reuse excess heat in the same process stream and improve solid-liquid separation duties with more efficient, space-saving decanter centrifuges. Alfa Laval’s know-how, equipment and services help recover water, energy, chemicals, and minerals thereby increasing productivity.

Zinc

Limited supply, fluctuating prices and rising costs pose challenges for the global zinc producers. Yet demand for zinc remains steadfast for steel galvanization, brass production, coatings for other metals, paints and primers as well as a variety of new applications. Successful production requires reliable, low-maintenance, resource-efficient equipment that minimizes costs and maximizes yield.

Nickel

Nickel producers face many challenges – from reducing energy, chemicals and environmental costs. Getting the most out of lateritic or sulfidic ores requires a trustworthy partner. Alfa Laval’s vast expertise with nickel refining processes and a broad equipment and services portfolio helps reduce costs and environmental impact, recover valuable minerals and by-products, and increase yields.

Uranium

Uranium production requires a deep understanding of how to best process varying ore compositions and cutting-edge technologies that reduce the use of energy, water and chemicals. From heating and cooling, leaching and thickening to solvent extraction, precipitation and enrichment, uranium producers count on Alfa Laval for heat transfer, separation and fluids handling equipment that optimize processes and boost yields.

Lithium

The extraction of lithium involves processes that are both energy- and water-intensive. The challenge lies in effectively managing energy and water usage to minimise environmental impact and maximise recovery rates. As demand for lithium surges due to its importance in electric vehicle batteries, producers need advanced technologies and reliable equipment to improve efficiency.

On the pulse of mineral processing

Alfa Laval help alumina, copper, zinc and nickel producers get the most out of raw ores – cost-effectively, energy-efficiently and in an environmentally friendly way. From smart reuse of process waters and recirculation of cooling waters to treatment of bleed streams and smart solid waste reduction, count on Alfa Laval.

Smart reuse of the vast amounts of heat involved in these processes can contribute directly to the bottom line. While dewatering and separation technologies help extract valuable by-products, reduce waste streams, and minimize environmental impact. Alfa Laval has the process know-how as well as a broad portfolio of equipment and services to help metal producers cut costs, achieve significant energy savings and raise yields.

Big energy savings through heat transfer

Beneficiation, digestion, roasting, leaching, smelting and electro-winning are all energy-intensive processes. By harnessing the heat generated during extraction processes and reusing it in other processes, metal producers not only save big on energy costs, but also boost productivity.

Our heat exchangers (gasketed, welded or spiral) are a proven and highly efficient technology for heat transfer to feed the heat back into the process with unparalleled yield. The heat exchangers’ close temperature approach, high internal turbulence and large heat-transfer areas combine to squeeze out up to 30% more energy than conventional shell-and-tube units out of every heat flow. By replacing costly and bulky units with Alfa Laval heat exchangers, processing plants can save cost and many megawatts of hidden energy each year.

Optimizing separation efficiency

Whether used for solvent extraction, electrowinning, dewatering, recovery of intermediate products, or separation processes, Alfa Laval centrifugal separators are reliable, resilient and equipped to deal with the complex solid-liquid or solid-liquid-liquid separation involved in mineral processing.

Due to highly efficient operation, robust design and the resulting high purity output, Alfa Laval separation solutions are an integral part of nearly all processes in the recovery of mineral raw materials. Which is why metal producers the world over rely on Alfa Laval to help maximize productivity and increase yields.

Alfa Laval decanters revolutionize coal mine tailings management strategy

The Rix’s Creek coal mining operation, part of the Bloomfield Group, set out to improve its onsite coal tailings management as part of its sustainability strategy to reduce water and energy consumption and minimize the surface footprint of waste handling processes.

Learn more

Read more about the efficiency, practicality and technical details of our range of equipment for solid-liquid separation in base minerals and mining by downloading the brochure.

Ways to raise plant profitability

Are you are looking for ways to raise plant profitability in your mineral and mining applications, contact Alfa Laval today to learn more about our proven technology and cost efficient solutions.