2015-04-02 Știri

Alfa Laval launches new, innovative oils & fats solutions at the OFI exhibition in Munich

At the Oils & Fats International exhibition in Munich, Germany, from September 18-20, 2013, Alfa Laval – a global supplier to the vegetable oil and animal fat industries – presents a variety of new innovative solutions with focus on high yield and sustainability.

At Alfa Laval’s stand no. 304 in hall B0 at OFI in Munich, visitors will get the opportunity to hear about the company’s many widely recognized process solutions as well as several new innovations that offer sustainable alternatives to traditional processing technologies.

For producers of vegetable oil, protein etc.

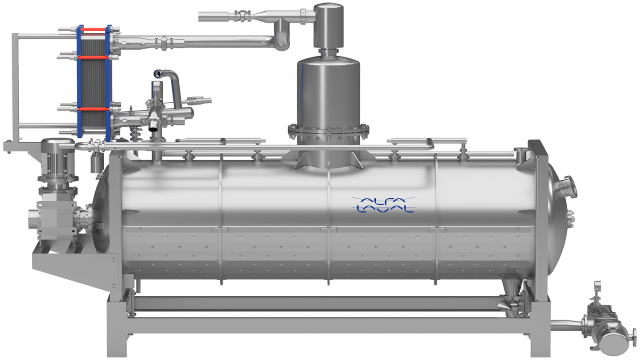

- Alfa Laval SoftColumn Dual-Strip, a new process for physical refining with continuous deodorization and deacidification especially suitable for very large capacities. It is a further development of the company’s widely used packed column technology. Compared to standard deodorization technologies, the Dual-Strip process delivers oil with improved quality and maximum efficiency.

- Enzymatic degumming with biological catalyst for gum removal, combined with SoftColumn continuous deodorization has demonstrated its value at numerous vegetable oil refineries. Benefits include up to 2% oil recovery, less consumption of chemicals and energy, less

by-products and effluent plus higher yield with same or even better oil quality. - Alfa Laval TocoBoost, a new technology (patent pending) to recover high value by-product streams enriched in micronutrients such as squalene or the highly potent tocotrienol antioxidants from the deodorizer vapour steam. These can be used for e.g. dietary supplements, health care and cosmetic products.

- High pressure hydrogenation, a new process for hardening of soft oils after bleaching and before deodorization. Operated at 20 Bar it generates less trans fatty acids plus allows faster production and higher capacity compared to low pressure hydrogenation at around 6 bar, for which Alfa Laval has delivered a number of plants.

- Processes for significant reduction of trans fatty acids(TFA), even to below 1%, e.g. allowing customers to change from chemical to physical refining

- Other oils and fats modification processes like post-refining (post-bleaching and deodorization of hydrogenated oil and fats) as well as chemical or enzymatic interesterification.

- Processes for extraction of vegetable protein, sugar and fibre from e.g. rape seed, sun flower, yellow pea,and granola.

For producers of animal fats and proteins

- FusionLine, a new invention for heating and cooling of pumpable fluids with meat, fish and other soft particles. It combines the open flow characteristics of tubular heat exchangers with the benefits of plate heat exchangers: thermal efficiency and pumping energy savings, improved product quality and full accessibility of product channels plus reduced product losses at an attractive investment level.

- Thermal hydrolyzation, a process that turns meat by-products into a high value fish feed ingredient with high nutritional properties. Hydrolysis offers a new business opportunity after the recently changed EU legislation that lifts the ban of using animal protein in all diets and now allows for the use (under certain circumstances) of processed animal proteins from category 3 material to be processed into fish feed.

- A wide range of energy efficient evaporation process solutions for concentration of stick water and hydrolisates in animal meat production such as rising and falling film technology and ConVap evaporation, providing a high level recovery of heat and proteins.

Biodiesel solutions

- Versatile Alfa Laval Ageratec processes for (trans-)esterification and advanced glycerol treatment (AGT) can turn virgin fats and oils as well inedible and high FFA by-products of vegetable or animal origin plus used cooking oil into biodiesel.

Presentation at Practical Short Course

On September 19 at 13.00 Andrew Logan from Alfa Laval will give the presentation “Zero Discharge in Refining” at the Practical Short Course: “Novel Technologies in Oilseed Processing, Edible Oil Refining and Oil Modification” taking place next to the Oils + Fats trade show.