2019-09-23 Știri

Alfa Laval’s new ALDEC G3 VecFlow™ decanter centrifuge cuts operating costs for sludge dewatering and thickening

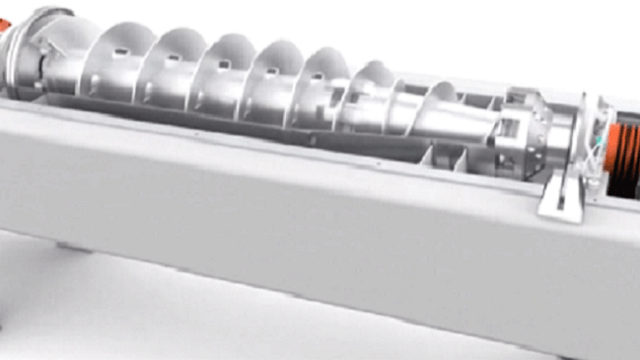

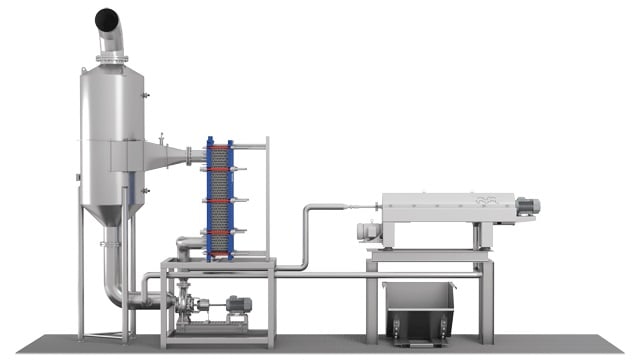

Alfa Laval will launch its new ALDEC G3 VecFlow™ decanter centrifuge for sludge dewatering and thickening at the WEFTEC exhibition in Chicago, September 23-25. The new decanter centrifuge features Alfa Laval’s unique VecFlow™ feed zone that reduces power consumption by 30% while increasing separation performance.

Reducing power consumption by 30%

Minimal turbulence is the key to low power consumption and high separation performance in a decanter centrifuge. Alfa Laval’s new VecFlow™ feed zone injects sludge in a way that has minimal effect on the flow inside the decanter bowl. This reduces turbulence by more than 80% compared to traditional decanter centrifuges and overall power consumption by 30%.

High separation performance

The decanter’s low turbulence further boosts separation performance, which allows plants to optimize processes by increasing dry solids percentage, reducing consumption of flocculants or increasing throughput. A flexible control system makes it easy for operators to balance these benefits according to the specific priorities of their operation.

An upgrade for ALDEC G3 owners

For customers already operating ALDEC G3s, it will be possible to upgrade their decanters with a new conveyor featuring the VecFlow™ feed zone. This will increase separation performance and lower the power consumption to the same level as an ALDEC G3 VecFlow™.

Launched at WEFTEC

The ALDEC G3 VecFlow™ will be launched at the WEFTEC exhibition in Chicago, September 23-25 and be on display in Alfa Laval’s booth (1621). Carl Rehncrona, Vice President and Head of Sales at Business Unit Decanters and Membranes, Alfa Laval is looking forward to the launch. “We continue to push the boundaries in sludge dewatering and we are excited to show visitors at WEFTEC our new ALDEC G3 VecFlow™. The combination of low operating costs and exceptional separation performance gives short payback times – often less than a year,” he says. “The possibility to upgrade existing ALDEC G3s is a good example of how we at Alfa Laval always aim to give our customers maximum value throughout the entire lifetime of the equipment. When you invest in an Alfa Laval decanter you have a platform that will be ready for the future and serve you for many years,” Carl Rehncrona concludes.

To learn more about the new Alfa Laval ALDEC G3 VecFlow™, visit www.alfalaval.com/vecflow

For further information, please contact:

Carl Rehncrona

Vice President, Head of Sales, Business Unit Decanters

Phone: +46 709 36 67 87

E-mail: carl.rehncrona@alfalaval.com

Taha Suria

Global Sales Manager, Water & Waste, BU Decanters, Food & Water Division

Phone: +45 27 77 84 01

E-mail: taha.suria@alfalaval.com

Susanne Rosentoft

Marketing Communication Manager F&W, PD Corporate Communications

Phone: +45 51 51 41 63

E-mail: susanne.rosentoft@alfalaval.com

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2018, posted annual sales of about SEK 40.7 billion (approx. 4.0 billion Euros). The company has about 17,200 employees.